Injin Cika Tubu don filastik laminate da bututun aluminium (har zuwa 320 ppm)

BAYANIN KYAUTA

Taƙaitaccen Bayanin Injin rufe bututun filastik

1. Theroba bututu sealing injiyana amfani da Siemens 10-inch touch allon da Jafananci Keyence PLC-KV8000 software sarrafa.

2. bututu na tsarin sarrafa filler servo aiki da dabarun sarrafa motsi

3. Ayyukan sarrafawa: Bayan an cire bututu ko fitarwa, har yanzu akwai bututu da ke zama a cikin sarkar bututu - rufewa.

4. Ayyukan tsaro (tsayawa ta gaggawa da maɓallin kariya) duk kofofin suna kulle lokacin da bututun filler ke gudana.

5. atomatik bututu cika injiyana da Duk na'urorin ƙararrawa da aka kwatanta za'a iya daidaita su ta hanyar kula da panel

6. Sabis na lantarki na bututu na filler na iya daidaita saurin daidaiku, kuma ana iya daidaita saurin samar da injin duka.

7. Na'urar inching tana aiki a ƙananan gudu

8. Babban panel don daidaita duk saitunan samarwa

9. Ƙungiyar aiki tana nuna yawan samarwa da matsayi na layi

10. Dangane da buƙatun abokin ciniki, saita ƙididdiga masu yawa don bututu na filler

11. Theatomatik bututu cika injiƘungiyar sarrafawa na iya saita ayyukan siga

12. Na'urar cika bututu ta atomatik tana da sashin aikin da aka kiyaye ta matakan aiki daban-daban na 3.

13. Bakin karfe mai zaman kansa na lantarki tare da kwandishan, matakin kariya ya kai IP65 ko sama.Tayoyin kebul tsakanin kabad ɗin lantarki da injina suna amfani da rufaffiyar trays na USB, kuma igiyoyi suna shiga daga saman na'urar a babban matakin.

A nan gaba, tsarin sarrafawa na iya amfani da Siemens profitnet don canja wurin bayanai zuwa MES da haɗi tare da tsarin MES.

Injin Cika Tubu don Plasticlaminate da bututun aluminum

Saukewa: LFC4002Injin Cika Bututuna'ura ce mai cika tashoshi huɗu da rufe cikakken servo filastik bututu mai ɗaukar hoto mai zaman kansa wanda kamfaninmu ya ƙirƙira da kera shi.Ya dace da cika ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun abubuwa na bakararre ko bakararre aluminum-plastic composite tubes, bututun filastik da bututun aluminum.Matsakaicin saurin ƙira shine bututun 360 / minti, kuma ainihin matsakaicin matsakaicin saurin samar da bututun bututu shine bututun 250-340 / minti.Daidaiton cikawa shine ≤± 0.5%.An rufe bututun aluminium ta hanyar nadawa, bututun aluminum-plastic composite bututu ana rufe shi ta iska mai zafi ko dumama mai girma, kuma bututun filastik an rufe shi ta hanyar dumama iska mai zafi.

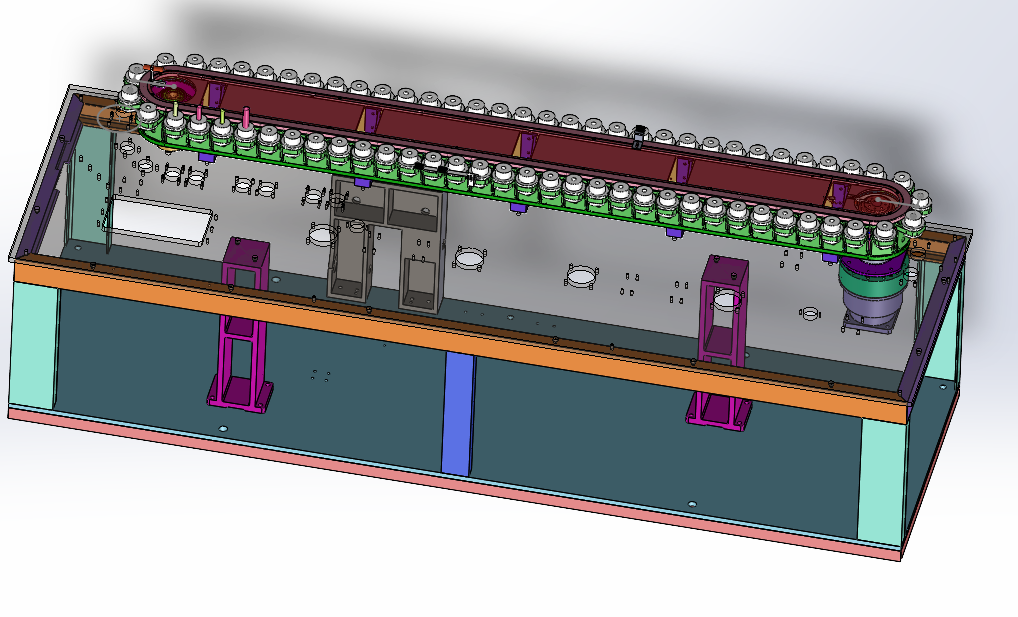

Tubus Cika Inji Babban tsarin watsawa:

Injin cika bututu ta atomatikyana ɗaukar hanyar dogo mai jagorar gami da ƙarfe mai ƙarfi, injin hana girgiza mai ɗaukar bututu mai ɗaukar nauyi mai ɗaukar nauyi mai ɗaukar nauyi, da saitin 4kW servo mai sarrafa bututu mai ɗaukar nauyi mai ɗaukar nauyi.Na'urar rufe bututun filastik yana ƙayyade matsakaicin saurin gudu da kwanciyar hankali na kayan aikin marufi.

Tubus Filling Machine tube kofin sarkar isar da na'urar ta ƙunshi manyan raƙuman ruwa na sama, ƙasa da gefen haɗin gwal na jagora.Ana shigar da birgima guda uku akan kujerar kofin bututu, kuma birgima bearings suna motsawa a cikin ramuka kuma suna fitar da bututun.Sarkar kofin tube ba shi da lalacewa.Har ila yau, akwai nau'ikan allura biyu na sama da na ƙasa waɗanda aka ɗora akan fil don juyawa.

Na'ura mai rufe bututun filastik Mai ɗaukar sarkar bututun tiyo tana gyara kujerun bututu (matsayi mai ɗauka uku, titin jagorar ƙarfe) ga juna ta bel mai ɗaukar haƙori.Belin na'ura mai haƙori yana gudana daidai da yanayin watsa motsin tuƙi.Ana ɗora kofin bututu akan kowace zoben wurin zama.An yi kofin bututu da kayan POM kuma ya dace da ƙayyadaddun bututu da buƙatun ƙira.

Tubus Cika Injin isar da sarkar wuce gona da iri ana yin kariya ta asali ta daidaitaccen madaidaicin juzu'in juzu'i wanda aka sanya akan dabaran watsawa, wanda ke da tsawon rayuwar sabis.Idan sarkar bututun ta makale, an katse clutch, an kunna kusancin, kuma injin ya tsaya nan da nan.

Tubus Cika Injin Tsabtace Kan layi

1. Injin rufe bututun filastikZa a iya tsabtace tsarin cikawa da hopper ta atomatik ta tashar CIP a cikin rufaffiyar madauki a lokaci guda.

2. Kafin fara CIP, an shigar da bututun cikawa tare da takamaiman CIP dummy kofin, kuma za a fitar da ruwan tsaftacewa daga injin cikawa ta bututun da aka haɗa da kofin CIP dummy.

3. Cibiyar aikin CIP (wanda abokin ciniki ya ba da shi) yana ba da wakili mai tsaftacewa zuwa ƙofar hopper.Ana shigar da ƙwallon feshi a cikin silinda, kuma ƙwallon fesa yana fesa wakili mai tsaftacewa a saman ciki na Silinda.An tsara tsarin cika injin bututun filastik bisa ga ka'idodin tsabta, kuma ruwan tsaftacewa na CIP na iya isa ga duk saman, bututu da kayan aikin da suka haɗu da samfurin yayin aikin samarwa.Matsar da sassan da ke haɗuwa da samfurin yayin aikin samarwa, kamar famfo na piston, masu tayar da hankali, da dai sauransu, za su kuma juya daidai lokacin tsaftacewar CIP don tabbatar da cewa za a iya tsaftace dukkan sassan sassan motsi.

4. Bututu mai haɗawa don ruwan tsaftacewa don komawa tsarin CIP na abokin ciniki (ba a haɗa famfo mai dawowa a cikin iyakar wadata ba)

5. Kafa tsaftacewa da zagayowar disinfection bisa ga bukatun abokin ciniki, kuma ana saita duk tsaftacewa da lalata a cikin tashar CIP.

6. Za'a iya saita ma'auni kamar zafin jiki, matsa lamba, yawan ruwa da lokaci na sake zagayowar CIP ta tashar CIP bisa ga bukatun abokin ciniki.

7. Hakanan za'a iya cire bututun mai cika bututun filastik na injin rufewa da sauri daga tsarin famfo don tsaftacewa ta layi.

8.CIP zirga-zirga yana buƙatar 2T / H ko sama

Injin Cika Tubus suna ɗaukar mutummutumi don ciyar da bututu (15x2 bututu da aka ɗauka a cikin layuka biyu kowane lokaci, sau 9-12 / minti):

Bisa tsarin da aka tsara, robobin na fitar da hoses guda biyu a kowane lokaci daga cikin kwalin bututun da aka kafa a kowane lokaci, ya kai su saman kofin bututun, sannan a saka su a tsaye a cikin kofin bututun.Mutum-mutumi yana amfani da hanyar tallafin bututu, kuma yana amfani da bakin karfe don matsar da yatsunsu.Kerarre, ana iya tarwatsawa don tsaftacewa da lalata ko kuma a lalata shi da feshin hydrogen peroxide.

Gilashin ɗin yana gano ko akwai lefen bututu a cikin yatsan mutum-mutumin da ba a saka shi a cikin kofin bututun ba, kuma yana kunna injin cirewa don cire tiyo daga yatsa, sannan ya ci gaba da ɗaukar bututun.

LFC4002 Tubes Filling Machine yana da fa'idodi masu zuwa:

a.Tsarin sarrafawa: Bututun filler yana ɗaukar allon taɓawa na Siemens da mai sarrafa motsi na Keyence na Jafananci, cikakken bas ɗin servo;amo bai wuce 75 decibels ba.

b.Tsarin ƙididdigewa: bututu na filler yana amfani da tsarin servo azaman mai ƙididdigewa, kuma yana haɓaka software daban-daban don haɓaka ƙarfi zuwa daidaitaccen rabo, ƙara tsayin lokacin cikawa da hatimi, da tabbatar da cewa ingantaccen saurin kayan aikin yana sama da 260pcs / min.

c.Jagorar Sarkar Kofin Kofin: Injin cika bututu ta atomatik yana ɗaukar aikin tashar tashoshi huɗu, layin dogo na haɗin gwiwar ƙarfe na ƙarfe, da injin kulle-kulle mai ɗaukar hoto mai ɗaukar hoto uku.

d.Rarrabuwar wurare: tiyo mai tsabtace kai, ɗigon bututun robot, ɗigon bututun servo, saukar da bututu ta atomatik, cikawa da rufewa, zubar da bututun servo da sauran wuraren an rabu bisa ga buƙatun GMP.

e.Matsayin akwatin bututu: Injin cika bututu ta atomatik yana ɗaukar jigilar mai Layer biyu.Ana jigilar akwatin bututun akan saman saman, an saita shi akan dandamali mai karkata, kuma akwatin mara komai yana dawowa akan ƙaramin Layer.

f.Hanyar ɗora Tube: Na'ura mai ɗaukar nauyi na Robot ko bututu ta shiga cikin bututu, kuma tana iya adana bututun 3000-4000.

h.Alamar alama ta Servo: siginar alamar launi mara lafiya, babban jujjuyawar juzu'i na servo, babban sauri da kwanciyar hankali.

i.Cikawar Servo: Injin cika bututu ta atomatik yana ɗaukar tukin servo mai cikakken layi da cikakken famfon yumbu, wanda ba zai taɓa ƙarewa ba.

j.Aluminum clamping tube clamping and flattening: The clamping and flattening in the climping the med sealing na'urar asalin wani almakashi-nau'in clamping flattening, wanda zai iya sauƙi danna iska a cikin bututu.Yanzu an canza shi zuwa tsarin matsewa a kwance da lallausan ƙasa, wanda ba shi da ƙura kuma yana guje wa tuƙin gas a cikin bututu.

k.Aluminum bututun hatimin wutsiya: Lokacin rufe wutsiya, nadawa da matsawa suna ɗaukar motsi madaidaiciya madaidaiciya (asali nau'in ɗaukar baka) motsi ba tare da ja bututun zuwa sama ba.Wannan ya dace musamman ga wutsiyoyi masu ninki uku.

n.Na'urar fitarwa: Sabis ɗin yana fitar da bututun ta hanyoyi huɗu kuma yana da aikin ƙin yarda.

o.Isar da aiki tare: motsi na tsaka-tsaki na servo, jigilar ruwa daban, aiki tare mai kyau.

p.Hopper mai matsa lamba: yana ɗaukar yanayin buɗe sauri na bututun rarraba don haɗawa da famfo mai cikawa.

q.CIP na kan layi: Ana iya tsaftace shi akan layi ko a layi.

Sigar fasaha

- Tubes Cika Inji Babban sigogin fasaha na kayan aiki

| No | siga | kalamai | |

| Bayanin Tube (mm) | Diamita 13 ~ 30, Tsawon 60 ~ 250 |

| |

| Matsayin alamar launi (mm) | ± 1.0 |

| |

| iya cika (ml) | 1.5 ~ 200 (Haɗu da 5g-50g ƙayyadaddun bayanai, ƙayyadaddun ƙayyadaddun bayanai da girma bisa ga iri-iri da fasaha) |

| |

| Cika daidaito (%) | ≤± 0.5 |

| |

| Rufe wutsiyoyi | Akwai nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan iri uku da nau'ikan sirdi. |

| |

| Ƙarfin fitarwa PPm | 250-300 |

| |

| Bututu mai dacewa | Aluminum bututu Filastik bututu Aluminum filastik bututu |

| |

| Amfanin wutar lantarki (kW) | tube na filler | 35 |

|

| Robot | 10 |

| |

| Ƙarfi | 380V 50Hz |

| |

| karfin iska | 0.6MPa |

| |

| Amfanin iska (m3/h) | 20 zuwa 30 |

| |

| Tsarin sarkar watsawa | (An shigo da shi daga Italiya) Nau'in bel na aiki tare (servo drive) |

| |

| tsarin watsawa | Cikakken faifan servo |

| |

| girman (mm) | Tsawon 3700 Nisa 2000 Tsawo 2500 |

| |

| Jimlar nauyi (kg) | 3500 | ||

Smart zhitong yana da ƙwararrun ƙwararrun masu ƙira, waɗanda za su iya ƙiraInjin Cika Bututubisa ga ainihin bukatun abokan ciniki

Da fatan za a tuntuɓe mu don taimako kyauta @whatspp +8615800211936

Rukunin samfuran

-

Imel

-

Waya

-

Sama

0086 15800211936

0086 15800211936