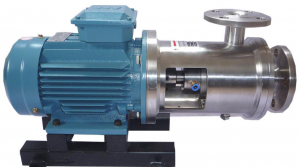

Babban Shear Inline Homogenizer

Fasalolin Zane-zane na Homogenizer

Inline Homogenizer gabaɗaya yana nufin na'urar haɗaɗɗen ci gaba da ake amfani da ita don ci gaba da haɗawa da daidaita ruwa, ƙaƙƙarfan ko ƙarancin ƙarfi a cikin layin samarwa.Ana amfani da irin wannan nau'in kayan aiki a cikin magunguna, abinci, kayan kwalliya, robobi da sauran masana'antar sarrafa kayan.

Inline Homogenizer yawanci ya ƙunshi babban juyi mai jujjuyawar sauri da tsayayyen stator tare da ƙaramin tazara tsakanin su.Lokacin da kayan ya wuce ta cikin kayan aiki, rotor yana jujjuya kuma yana yin babban ƙarfi akan shi, yana haifar da ƙarin haɗuwa da haɗuwa yayin da yake wucewa ta rata tsakanin rotor da stator.

Abubuwan amfani da wannan kayan aiki sun haɗa da ikon ci gaba da haɗawa da haɓaka kayan aiki akan layin samarwa, tare da haɓakar haɓakawa da inganci, da ikon sarrafa nau'ikan kayan daban-daban, gami da danko, fibrous da kayan granular.Bugu da kari, Inline Homogenizer yana da ƙaramin sawun ƙafa, ƙaramin ƙara, kuma yana da sauƙin tsaftacewa da kiyayewa.

Fa'idodin Inline Homogenizer (kayan ci gaba da haɗawa) galibi sun haɗa da:

1. Homogenizer famfo yana amfani da babban ingancin SS316 bakin karfe, wanda yana da kyau plasticity, tauri, sanyi denaturation, walda aiki yi, da kuma polishing yi.

2Ci gaba da aiki: Ba kamar batch hadawa da hada kayan aiki, Inline Homogenizer na iya cimma ci gaba da hadawa da samarwa, ta haka inganta samar da inganci da fitarwa.

3. Babban haɓakar haɓakawa: Wannan kayan aiki na iya samar da haɓakar haɓakar haɓakawa da rarraba kayan aiki daidai, tabbatar da inganci da daidaiton samfurin ƙarshe.

4. Ingantacciyar amfani da makamashi: Tsarin shearwa da haɗuwa na Inline Homogenizer na iya rage yawan amfani da makamashi da haɓaka amfani da makamashi.

5. Zai iya ɗaukar kayan aiki iri-iri: Wannan kayan aikin na iya ɗaukar nau'ikan kayan daban-daban, gami da kayan viscous, fibrous da granular, kuma yana da fa'ida.

6. Ƙananan sawun: Inline Homogenizer kayan aiki ne m kuma yana da karamin sawun, wanda zai iya rage ma'aikata sarari bukatun.

7. Sauƙi don tsaftacewa da kulawa: Kayan aiki yana da tsari mai sauƙi kuma yana da sauƙin rarrabawa da tsaftacewa, rage lokaci da farashin tsaftacewa da kulawa.

8. Ƙarfafawa mai ƙarfi: Zai iya daidaitawa da nau'o'in samarwa daban-daban da bukatun tsari, da kuma haɗawa da kayan aiki daban-daban don tabbatar da ci gaba da kwanciyar hankali na tsarin samarwa.

Siffofin ƙirar Inline Homogenizer sun haɗa da abubuwa masu zuwa

1. Ci gaba da hadawa: Ba kamar masu haɗawa ba, Inline Homogenizer na iya cimma ci gaba da haɗuwa da samarwa, ta haka inganta ingantaccen samarwa, fitarwa, da daidaiton tsari.

2. Babban ƙarfi mai ƙarfi: Akwai ƙarfin ƙarfi mai ƙarfi tsakanin rotor da stator a cikin kayan aiki, wanda zai iya haɗawa da sauri da daidaita kayan da ke wucewa ta cikin su.

3. M rata: Rata tsakanin rotor da stator ne sosai kananan, wanda zai iya samar da finer hadawa da homogenization effects.

4. Juyawa mai saurin gudu: Rotor yana jujjuya cikin sauri mai girma, ta haka yana haifar da ƙarfi mai ƙarfi.Gudun juyawa zai iya bambanta dangane da aikace-aikacen.

5. Yawan girma da nau'ikan: Za'a iya tsara ƙirar Homogenizer na Inline don takamaiman aikace-aikace da nau'ikan kayan aiki.Daban-daban masu girma dabam da nau'ikan kayan aiki na iya saduwa da buƙatun samarwa daban-daban.

6. Sauƙi don tsaftacewa da kulawa: Inline Homogenizer ya kamata a tsara shi tare da sauƙi na tsaftacewa da kiyayewa a hankali don kiyaye kayan aiki mai tsabta da tsabta yayin aikin samarwa da sauƙaƙe kulawa da dubawa na yau da kullum.

7. Daidaita da nau'o'in samarwa daban-daban: Tsarin Inline Homogenizer ya kamata yayi la'akari da daidaitawa ga nau'o'in samarwa daban-daban da bukatun tsari, irin su haɗawa tare da famfo daban-daban, bututun, bawuloli da sauran kayan aiki don tabbatar da ci gaba da kwanciyar hankali na tsarin samarwa.

8. Gudanar da hankali: Za'a iya samar da ƙirar Homogenizer na Inline tare da tsarin kulawa mai hankali don gane aiki ta atomatik, saka idanu da kiyaye kayan aiki, inganta ingantaccen samarwa da ingancin samfur.

Gabaɗaya, fasalulluka na ƙirar Homogenizer na Inline sune ci gaba da haɗawa, ƙarfin ƙarfi mai ƙarfi, tsattsauran rata, jujjuyawar sauri, nau'ikan girma da yawa, sauƙin tsaftacewa da kiyayewa, da daidaitawa zuwa layin samarwa daban-daban da kulawar hankali.Waɗannan fasalulluka sun sa Inline Homogenizer ɗaya daga cikin kayan haɗaɗɗen haɗawa da kayan haɗin kai da aka fi amfani da su a yawancin filayen masana'antu.

Lab Homogenizer inline homogenizer Motar

HEX1 jerin don a cikin Line Homogenizer Teburin sigogi na fasaha

| Nau'in | Iyawa | Ƙarfi | Matsin lamba | Shigar | Fitowa | Gudun juyi (rpm) | Gudun juyi (rpm) |

| (m³/h) | (kW) | (MPa) | Dn (mm) | Dn (mm) | |||

| HEX1-100 | 1 | 2.2 | 0.06 | 25 | 15 | 2900 | 6000 |

| HEX1-140 | 5 | 5.5 | 0.06 | 40 | 32 | ||

| HEX1-165 | 10 | 7.5 | 0.1 | 50 | 40 | ||

| HEX1-185 15 11 0.1 | 65 55 | ||||||

| HEX1-200 | 20 | 15 | 0.1 | 80 | 65 | ||

| HEX1-220 30 15 | 0.15 | 8065 | |||||

| HEX1-240 | 50 | 22 | 0.15 | 100 | 80 | ||

| HEX1-260 60 37 0.15 | 125 | 100 | |||||

| HEX1-300 | 80 | 45 | 0.2 | 125 | 100 | ||

Jerin HEX3 don cikin Layin Homogenizer

| Nau'in | Iyawa | Ƙarfi | Matsin lamba | Shigar | Fitowa | Gudun juyi (rpm) | Gudun juyi (rpm) |

| (m³/h) | (kW) | (MPa) | Dn (mm) | Dn (mm) | |||

| HEX3-100 | 1 | 2.2 | 0.06 | 25 | 15 | 2900 | 6000 |

| HEX3-140 | 5 | 5.5 | 0.06 | 40 | 32 | ||

| HEX3-165 | 10 | 7.5 | 0.1 | 50 | 40 | ||

| HEX3-185 15 11 0.1 | 65 55 | ||||||

| HE3-200 | 20 | 15 | 0.1 | 80 | 65 | ||

| HEX3-220 30 15 | 0.15 | 8065 | |||||

| HEX3-240 | 50 | 22 | 0.15 | 100 | 80 | ||

| HEX3-260 60 37 0.15 | 125 | 100 | |||||

| HEX3-300 | 80 | 45 | 0.2 | 125 | 100 | ||

Homogenizer Pump Shigarwa da gwaji

Rukunin samfuran

-

Imel

-

Waya

-

Sama

0086 15800211936

0086 15800211936